Overview

SMARTGUIDE.DF: TRIED AND TESTED SOLUTIONS FOR OPTIMAL WEB GUIDING

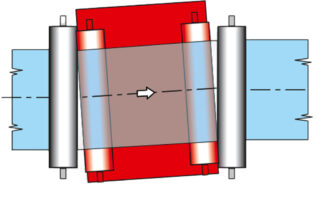

The main areas of application for the SmartGuide.DF are the printing and extrusion sectors. The BST rotating frame guide (DF) is also well suited for short control loops with low material demands. For ease of operation, the sensors can be moved by optional motor-driven sensor adjustment. This is especially beneficial for sensors that are difficult to move, web widths that frequently change, or special functions, like oscillation.

Modular Construction for Maximum Economy

Benefit from proven standards and an extensive range of equipment features. Through the SmartGuide.DF’s modular construction, customer-specific solutions can be carried out particularly efficiently. Simple retrofits are also possible at any time. The predefinition of characteristics ensures maximum transparency and simplifies technical clarifications.

The SmartGuide.DF is usable for all installation positions and wire threading.

If needed, the SmartGuide.DF can also be outfitted with AccuWeb components.

SmartGuide.DF System Equipment:

- Compatible with all standard edge sensors (optical or ultrasonic)

- Selectable control side

- Regulation by web edge

- Manual sensor adjustment

- Remote operation via digital inputs (digital I/O)

SmartGuide.DF Options:

- Object guiding with CLS CAM 100

- Line and contrast guiding with CLS Pro 600

- Regulation by web edge and web center-line (two edge sensors)

- Manual fine adjustment for one or both edge sensors

- Remote operation by additional commander

- Motor-driven sensor adjustment with automatic edge seeking and pre-positioning for edges and/or web center-line guiding with a set or variable web center (automatic edge search not possible with CLS Pro 600, CLS CAM 100)

- Basic: Bus systems: CAN, Ethernet UDP

- Advanced:Bus systems: CAN, Profibus DP, DeviceNet, or Profinet

- Remote operation configurable via digital inputs/outputs