Overview

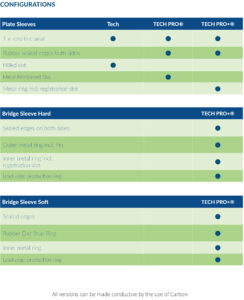

Tech Bridge is our most advanced bridge/adapter in the market. It is made using high-quality materials such as Dyneema for the inner layer and epoxy resin-infused fibreglass. This combination makes the bridge extremely durable and resistant to chemicals, heat and the stresses faced in a printing press.

- Extreme durability

- Built with the strongest materials

- Lead Edge full metal ring Protects the front edge of the bridge from damage by repeated handling of sleeves. Increases durability and lifetime.

- Separate Air A bridge to which the air is supplied by a separate air connection on the drive side of the press or mounting machine.

- Spacer sleeve (Only applicable to hard bridges) Provides the possibility to use sleeves of different widths on one bridge. The spacer sleeve provides a registration pin to align all sleeves on the operator side.

- Soft Coated Bridge The Soft Coated Tech Bridges are used to carry flexible, thin sleeves (seamless sleeves) which are available in densities of 40, 50 and 60 ShA. They can be Separate air connection or air-through.

- Miller Valves (Only applicable to Hard Separate air bridges) Control the air-flow of the bridge by covering the air holes with valves. Direct the air-flow to where required which creates flexibility to use multiple sleeve widths on one bridge with alignment on the drive side.