Overview

MatrixCutter

The MatrixCutter 140 is designed for handling adhesive matrix and edge trim waste from label printing and converting machines. Matrix and edge trim is captured directly in the machine and cut into small pieces in a granulator before being transported through piping system by a transport ventilator. The waste is then compacted in the integrated WasteCompactor.

- Increased machine speed as waste is no limitation.

- Reduced downtime as waste handling is always ready.

- No heavy lift by personal for handling of waste material

- No dust around the machines as the created dust is conveyed by the vacuum system.

- Reduced volume of waste by cutting and compacting the waste.

- Cost savings in disposal of the waste

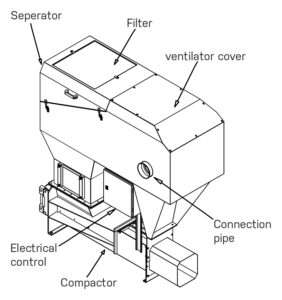

The Lundberg Tech MatrixCutter consists of

- Funnel

- Silencer

- Granulator

- Pipe system

- Ventilator with silencer inside the cabinet

- Separator

- Filter

- WasteCompactor

All parts transporting waste inside are anti stick coated or treated; which means no blocking due to waste material with glue sticking to the surface.

Specifications

| Maximum width of matrix | Up to 550mm |

| Maximum air capacity | 1600 m³ / hour |

| Maximum speed | 150 m / min |

| Maximum pipe | Dia. 160 |

| Maximum suction distance | Up to 10m |

| Size | 2114 x 980 x 2130 mm |

| Number of connected machines | 1 |

| Weight | 680 kg |

| Motor kW |

Granulator 1.1 kW Ventilator 2.2 kW Compactor 3,0 kW |

| Power | 3x400v |

| Sound | 50 Hz 68-72 dB |