Overview

Fully modular digital finishing

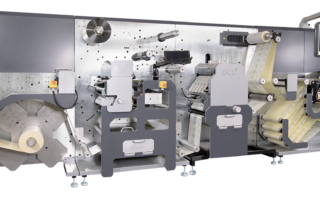

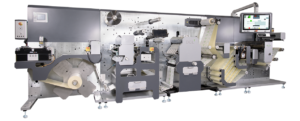

The DCL2 Modular Digital Finishing is a fully modular converting line made for finishing of pre-printed labels. This machine, which is fully servo driven, is built with the latest high-tech components available. Each module is designed for maximum performance to cut downtime to a minimum. The concept is 100% future safe, and you can add a new module onsite in only 8 hours.

Highlights

-

Most versatile solution on the market

- 100% modular

- Upgrade on site with any module in just 8 hours

- All our future innovations are available for existing customers.

- The most comprehensive portfolio of modules

- Innovative, automation features for non-stop production

Non-stop production featuresNon-stop buffer for continuous run Semi-automatic turret AUTOCUT automatic cut at end of roll and start of new cycle. Automatic die loadingQuick and easy change of flexible dies Easy to operate with step-by-step guide on operator panel. Time saving, user friendly solution. Flexible die change in 30 seconds Specialty modulesBooklet module Multilayer Label Module

|

Sci-Fi knivesFastest set up in the industry 1,5 second / knife Up to 15 knives across the web Min slitting width: 15 mm Embellishment modulesHot stamping and embossing from Pantec and Orthotec Flatbed screen printing Rotary Screen module Laser cutting powered by LasxHigh speed 100 m/min One laser source without stitching problems. |

Availible modules

Unwind modulesInline buffer for connection to printers Unwind 800 mm / 1000 mm with active brake system. Web-guide with line guide sensor Reel lift for heavy rolls Corona system Web cleaner Web de-curler. Automated Lamination and colf foil modulesLamination with carrier rewind and super lamination Cold foil system Rewind modulesServo driven rewind module for rolls up to 2 x 600 mm. Semi-automatic turret rewinder AUTOCUT automatic web cutting and start of new cycle. Rewind shaftsWith the new Q-SHAFT you turn 1 handle 1800 Q-SHAFT is quick, easy and hassle free Gigafast 210 M/MIN:High-speed semi-rotary die cutting module. |

Flexo print modulesFlexo printing module rotary / semi-rotary with UV / IR Dryer Re-register drive for over printing / in setting Chill roller for film/heat sensitive materials Die cutting modulesNew generation Semi-rotary die cutting system 110 m/min. Q-FLEX Automatic flexible die loading system Compensation program for flexible dies semi-rotary die cutting. Contact matrix waste rewind (snowball type) incl. back score unit. K+B Gapmaster with pressure control and oiling system Servo driven Sheeter with conveyor table Slitting systemsShear cut slitting system. SCI-FI KNIVES Automatic knife positioning Razor Blade slitting station Non-stop buffer module incl. additional ultrasonic web guide Servo Driven Fully Automatic Turret Module. For rolls up to 4×350 mm Additional fully automatic turret module Crush cut station. Auto set or manual under/back scorer |

Technical Specifications

Web widths: 350 mm / 450 mm / 550 mm

Max. speed rotary: 200 m/min

Max. speed semi-rotary: 110 m/min

Drive system: Servo

Unwind diameter: 800 / 1000 mm

Rewind diameter: 600 mm