Overview

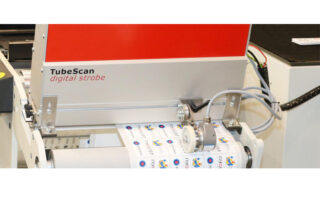

TubeScan

Print inspections solved intelligently

Introducing 100% print inspection that has never been as simple and cost-efficient as offered by the TubeScan product series.

From simple 100% web monitoring, detection of missing labels and matrix residues to high resolution 100% print inspection within a workflow – now you are able to realize all your needs with one modular system.

TubeScan inclusions:

- 100% web monitoring during make-ready and production

- Superb image quality dur to high camera resolution

- Automatic repeat synchronization across the entire speed range of the machine

- No health risk, less tiring compared to conventional monitoring using strobe lights

- Fast and easy job setup

- Very reliable and stable operation

- Suitable for narrow and medium-wide applications (180mm – 850mm web width)

- Cost-efficient and compact (outside dimensions: only 125mm in web direction)

Further options

- 100% print inspection

- Secondary inspection zones for individual tolerances

- Automatic label contour detection

- Masking function to ignore definable areas

- Surface inspection

- Distance monitoring with up to 8 reference points

- Placement control for rewinders

- Generation of PDF roll reports

- switchable UV-illumination (wavelength 365 nm)

- monitoring of backside printing through optimal, adjustable backlighting

- connecting through inspection workflow QLink

TubeScan eagle view at a glance:

- Cost-efficient combination of 100% print inspection and detail viewing, patented and unique worldwide

- Detail viewing of critical areas like registration marks, 2d barcodes, picture areas, etc. down to dot level

- Camera for detail viewing is motorized and can be easily navigated with respect to the displayed print repeat

- Switchable UV illumination (365 nm)

- No print mark sensor or gear sensor required for synchronization

- 100% live visualising from start of machine

- The optimal back light enables monitoring of the back print register

- Small foot print, only requires 125mm (5″) in web direction

- Can be combined with all options available for TubeScan digital strobe