Overview

SUPER COMPACT & PRODUCTIVE

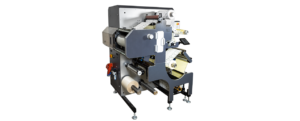

The new MCF Mega Compact Finishing is a fully servo driven machine for finishing of digital printed labels.

The machine is a compact version of the Converting Lines. It has a very compact design and small footprint (only 1,2 m) but can still finish most of your digital printed jobs thanks to lamination, semi-rotary, die cutting and slitting station.

Highlights

- Small footprint – only 1,2 m

- New design for easy operation and quick set up

- Innovative easy to change die loading system from the side

- Fast start up of new job

- Semi rotary die cutting, lamination and slitting in 40 m/min

Available Modules

Drive systemLatest servo technology for full web control Machine in solid construction and perfectly balanced Lamination moduleLamination self wound Lamination with carrier rewind Slitting systemRazor Blade slitting station Rewind shaftsWith the new Q-SHAFT you turn 1 handle 180o to change the shaft Q-SHAFT is quick, easy and hassle free

|

Intelligent unwind moduleUnwind unit 450 mm capacity with fixed unwind shaft Latest electronic web guide with ultrasonic sensor Adjustable splice table and integrated pneumatic web clamps Die cutting moduleQuick change of flexible dies Semi-rotary re-register servo driven 25″ repeat die station Anvil and support roller, including one 25″ magnetic die cylinder Servo driven matrix rewind Automatic pressure control Rewind unitServo driven rewind for rolls up to 450 mm diameter Adjustable rewind tension for hard to soft rolls, including 76 mm Q-SHAFT |

Technical specifications

Min. web width: 105 mm

Max. web width: 350 mm

Substrate thickness (self adhesive): 100-250 gsm

Max. mechanical speed: up to 40 m/min

Max. unwind roll diameter: 450 mm

Unwind shaft size: 76 mm [3″]

Max. speed lamination: up to 40 m/min

Lamination roll size: 450 mm