Overview

RHINO™ series

Profitable single pass decoration for exquisite labels

The market for high value consumer goods requires more and more highly embellished label designs. From exquisite single foil to complex multi foil designs: these labels attract buyer’s attention and assign a high value to the underlying product. They are therefore an essential cornerstone for the success of the brand owner. Combining the efficiency and versatility of flatbed technology, RHINO™ gives you the opportunity to offer outstanding labels for high-quality consumer goods at low additional cost.

Leading technology for brilliant decoration

- Perfect embossing results on uncoated, structured papers due to high stamping pressure and zero tolerance foil embossing

- Crisp, high embossing that lasts

- Longer dwell time, lower temperature, higher brilliance

- Small cost effective tools: quick setup

Consistently designed for performance and economy

- Quick setup of initial job – no foil cut needed

- Quick setup of repeat jobs – no finetuning required due to “job saver plate”

- Small, cost effective tools – No format parts

- Multifoil designs in single pass

- Two foil saving patterns optimize foil saving

Multifoiling and registered foils for outstanding designs

Lenses, 3D spatial effects and holographic foils are among the latest developments in label and packaging design. These unlock completely new design possibilities but only work if applied in perfect register.

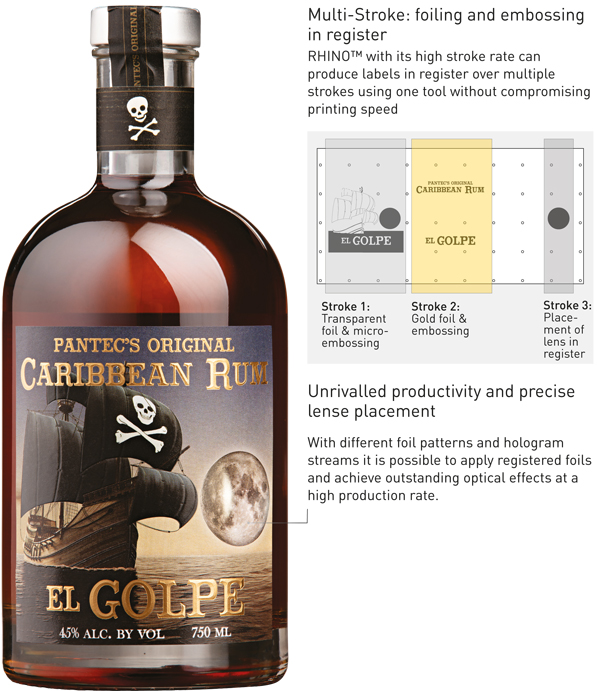

Multi-stroke = Multiple foils and embossing

RHINO™ enables the application of different foils in register using one tool. It´s even possible to emboss the substrate itself or just the foil to enhance its effect.

Placement of foils in register

With holographic foils and their optical effects labels will stand out even more. The transparent design of the lenses makes it possible to superimpose image

motifs, colors or logos with a unique holographic depth. In order for the optical effects of these new technologies to affect the packaging, the lenses must

be positioned in the register above the motif.

Made for efficient running

The fast foil change system, the Pantec shimming job saver plate and the job data storage are all designed to minimize changeover time. These unique features are particularly helpful for repeating jobs of which most can be setup in 8 – 12 minutes. The RHINO™ system can operate independently in a printing press and therefore be prepared even while the machine is running. In addition to the short changeover time, the unrivaled foil saving systemmakes RHINO™ the most efficient multi-stroke system on the market.

The advantage of two independent foil levels speak for themselves

In addition to the short changeover time, the unrivaled foil saving system makes RHINO™ the most efficient multi-stroke system on the market.

Looking on the “Camus” sample, the advantage of two independent foil levels is obvious. RHINO™ saves more foil than any other system on the market.

Designed for ease of use

An intuitive, user-friendly HMI makes it easier for the operator to run RHINO™. Its operating system is designed to support daily operation. Features include

- Process optimized servo control to ease foil transfer

- A self adapting register system

- The possibility to compensate for format deviation within RHINO™

- Easy job programming with foil waste optimization

All these functions help to use RHINO™ efficiently and to save money in every aspect of embellishment.

The RHINO™ series can be accessed remotely, giving Pantec the opportunity for fast and easy support. Whether there is a technical problem or the need for assistance in setting up the next job, the Pantec support is only just a click awa

Specifications

| RHINO™ S 410/510

Maximize your embellishment productivity. The RHINO™ S with its 30´000 strokes per hour is fully capable of operating in-line to printing presses dedicated to labels of high degree of embellishment Key data RHINO™ S 410/510 > Up to 30‘000 strokes per hour for high web speed

> Multi-stroke with 90° rotatable foil head in web direction or across the web > Two foiling levels for optimal foil saving > Application of registered foils |

RHINO™ E 410 / 340

Expand your embellishment capability The RHINO™ is best suited where running speed is not paramount, yet high quality embellished labels are still required. Key data RHINO™ E 410/340 > Up to 18‘000 strokes per hour:

> Multi-stroke with 90° rotatable foil head in web direction or across the web > Two foiling levels for optimal foil saving > Application of registered foils |