Overview

EFFICIENT MONITORING OF REGISTERS.

EFFECTIVE INCREASE IN QUALITY.

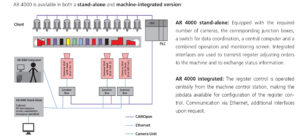

The economical solution for exact register settings: AR 4000 enables precise register adjustment with many machine types such as offset, hybrid and label printing machines. The precision solution features compact design,

intuitive touch screen operation and low installation efforts.

AR 4000 allows reliable adjustment of colour and front and back registers as well as reliable control of additional printing units (e.g. flexo printing units) or tool stations.

AR 4000 can bring you numerous benefits:

• Short set-up times

• Lower material consumption due to reduced waste in all printing stages

• Consistently high quality due to identical registers during the whole printing process

• Exact compliance with all register tolerances

• High-quality print products for increased customer satisfaction

Powerful technology for first-class quality:

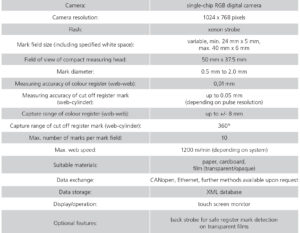

• Single-chip colour camera and intelligent image processing algorithms for secure and fast register mark detection even with rough material structures or poor contrast

• Xenon flash for optimal lighting even with critical substrates and reflecting materials

• Synchronised shutter for absolute insensitivity to extraneous light

• Large camera lens coverage for reliable detection of registration mark field, even with dynamic web stretching processes

Intuitive operation – clearly arranged visual interface:

• Single-monitor solution for presentation and operation via touch screen

• Customised user interface for every machine type

• Intuitive operation with multi-language user guidance and clearly arranged menus for easy, fast and convenient register monitoring

• Live colour image of the registration mark field of the selected measuring channel for easy assessment of quality and position of the registration marks

• Graphical representation of register errors for each individual measuring point

• Easy selection and simultaneous adjustment of register groups or all registers at the push of a button

• Fine adjustment of registers convenient by using arrow buttons or entering numeric values

Clever planning:

• One measuring head model for all register control points (web-web and web-cylinder) – one mark field for control of colour , front to back and cut off register

• Tested BST register micro-marks with diameters of only 0.5 mm – 1 mm; flexible arrangement of mark field in or across web running direction

• No additional marks with control of tool stations and additional printing units

• Web-cylinder method for front and back register control irrespective of material (transparent/opaque); optional webweb measuring process in combination with back strobe

• Web-web measuring method for additional printing units such as flexo printing units; web-cylinder measuring procedure for transparent varnish

• Compact measuring head integrates substantial system components and usually avoids the need for an additional panel

• Open system architecture for flexible machine integration; integration includes simple pulse control (PWM) up to direct control of the register motors and complete control panel integration, including job management and system operation by machine

• Only one measuring head per web side with standard offset printing applications, monitoring of up to ten printing units per measuring head.